DESCRIPTION

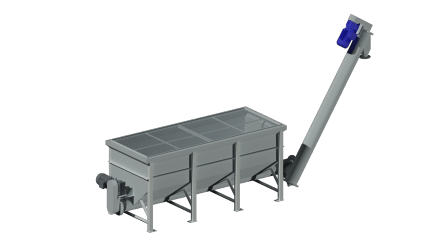

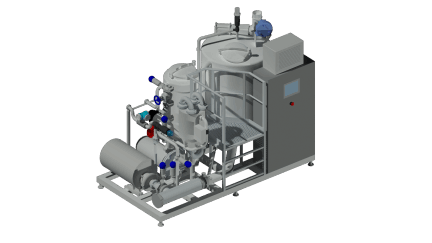

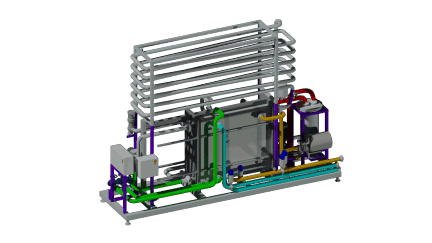

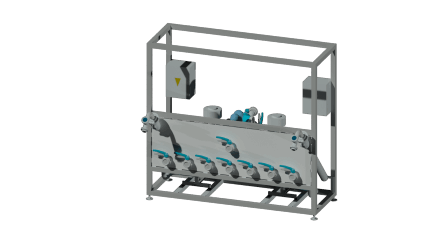

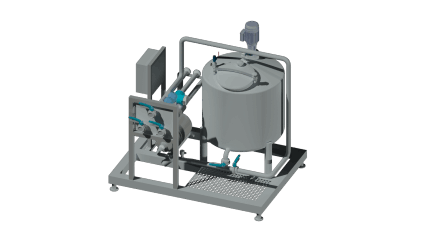

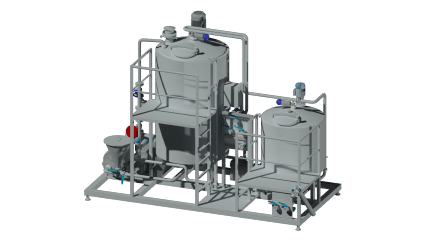

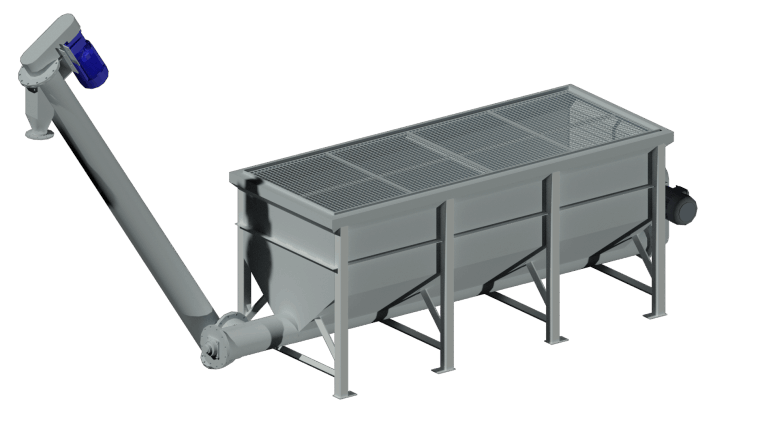

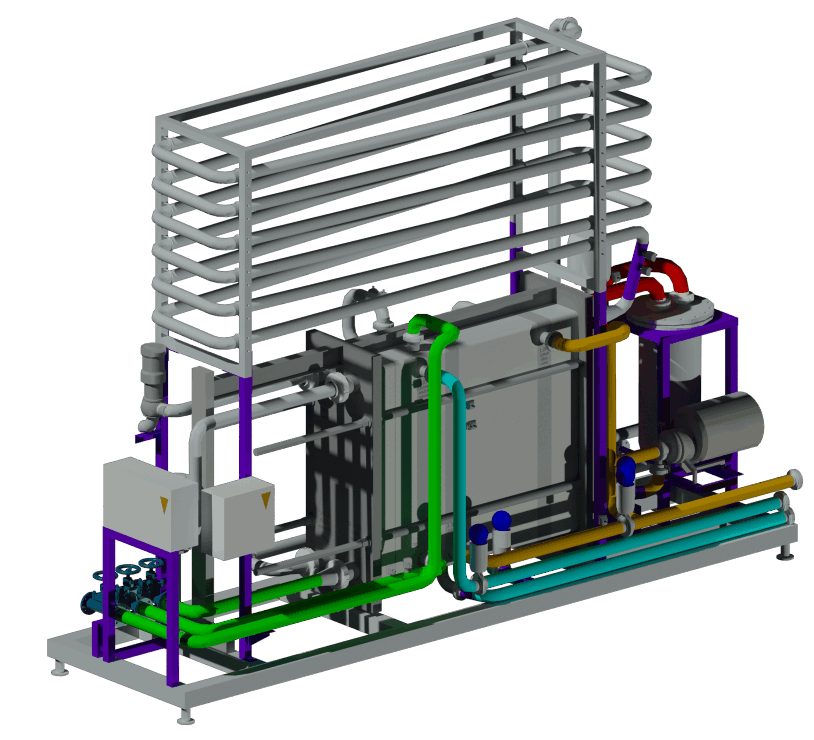

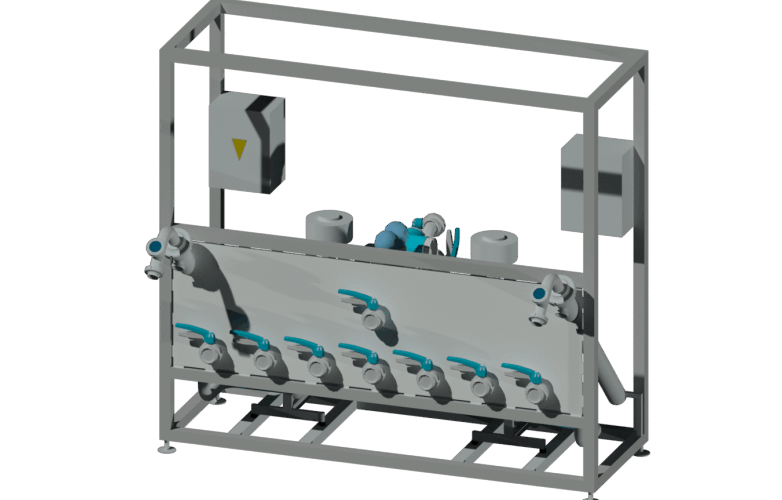

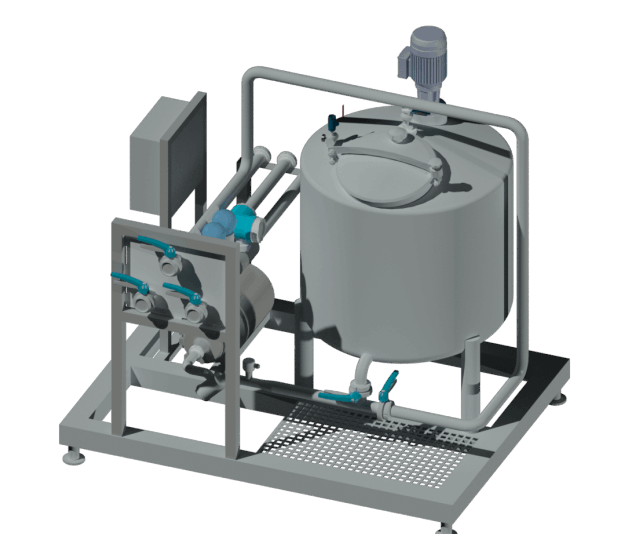

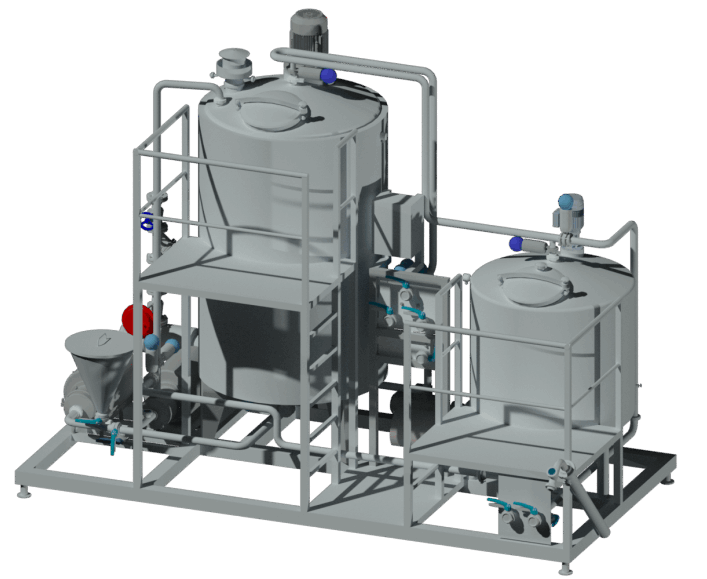

Combination of solutions simple syrup production in batch process or continuous system, with automatic adjustment of Brix up to 67º Brix, pasteurization time and filtering with filter bags to countries where sugar is white and refined with production capacity up to 25000L per hour. We provide dissolution at 85ºC or cold dissolution at 25º/41ºC depending on the rate and sugar quality. Automatic production System with load of sugar by screw conveyor or transport by vacum for a perfect dosing and a accurate final rightness of the Brix. All equipment presented may have an automatic programmed process individually

or grouped, depending on your needs as well as an HMI SCADA system with easy and intuitive design. Ability to control equipment by wireless remote or on site.